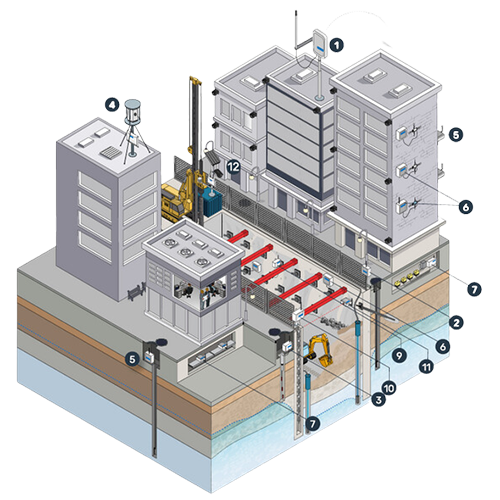

In the modern construction industry, monitoring key parameters has become essential for risk management and ensuring the longevity of structures. GridX solutions utilize advanced IoT technology for remote monitoring of all phases of construction and the condition of built structures. This technology enables continuous data collection and analysis, providing timely identification of potential issues, enhancing safety, and optimizing costs. By offering services as a solution, we allow clients to focus on the data while we handle the equipment and installation.

1. Remote management and monitoring of the network and all deployed devices, either on-site or via the cloud, using a gateway that transmits data to the Connection Management Tool (CMT). Integration of data analytics software into CMT enables comprehensive monitoring reports.

2. Assessment of groundwater level and water pressure using a Vibrating Wire single-channel data logger connected to a piezometer.

3. Measurement of soil displacement behind diaphragm walls and vertical deformations at various depths using a Vibrating Wire five-channel data logger connected to a multipoint extensometer or MPBX piezometer.

4. Supplementing geotechnical monitoring using a total station connected to ThreadX3 for precise motion tracking.

5. Measurement of tilt, building responses to tunneling, angular distortions, or horizontal displacements using the Tilt90, a 2-in-1 inclinometer and data logger, installed with a vertical mount.

6. Monitoring movements across surface cracks and joints related to tunneling using a Piconode or a Vibrating Wire single-channel data logger connected to a crack meter or displacement sensor.

7. Monitoring settlement, uplift, and building response to tunneling using an analog four-channel data logger connected to liquid settlement cells or a Wireless Tiltmeter attached to a rigid beam and installed in a series.

8. Measuring forces in ground anchors using a Piconode connected to a load cell.

9. Monitoring stress and strain in structural beams using a Vibrating Wire five-channel data logger connected to a strain gauge.

10. Analysis of lateral deformation of diaphragm walls and soil movement using a digital data logger connected to an embedded inclinometer (IPI) in a chain or a ShapeArray device in a borehole or excavation.

11. Collecting convergence data using the LaserTilt90, a 3-in-1 laser distance meter, inclinometer, and data logger with a range of 90°.

12. Integration of automated remote visual observation into your monitoring programs using an on-site camera connected to ThreadX3. Monitoring air dust concentration using an environmental monitoring sensor connected to ThreadX3.

Unesite svoj pojam za pretragu u polje ispod kako biste brzo pronašli sadržaj koji tražite. Pritisnite ‘Enter’ ili kliknite na dugme za pretragu da biste videli rezultate.